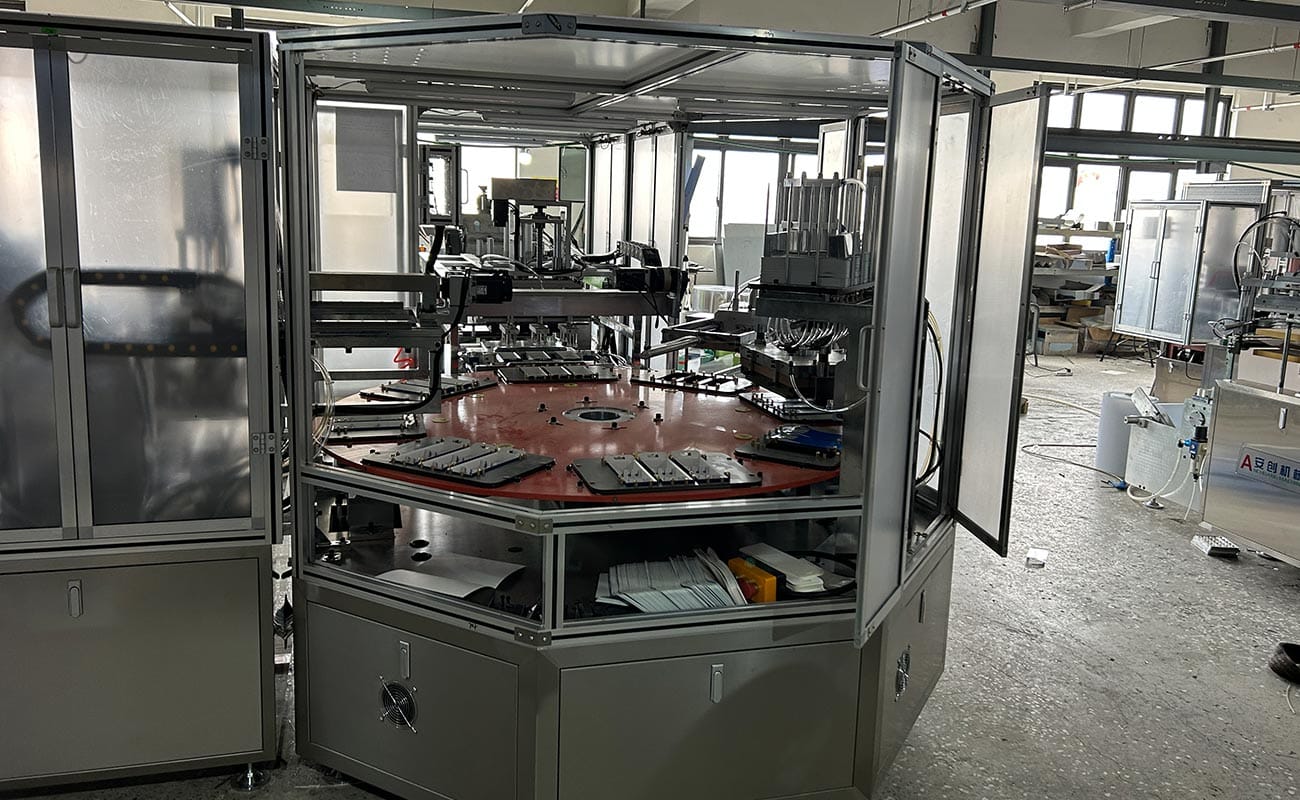

Double-sided paper card blister machine

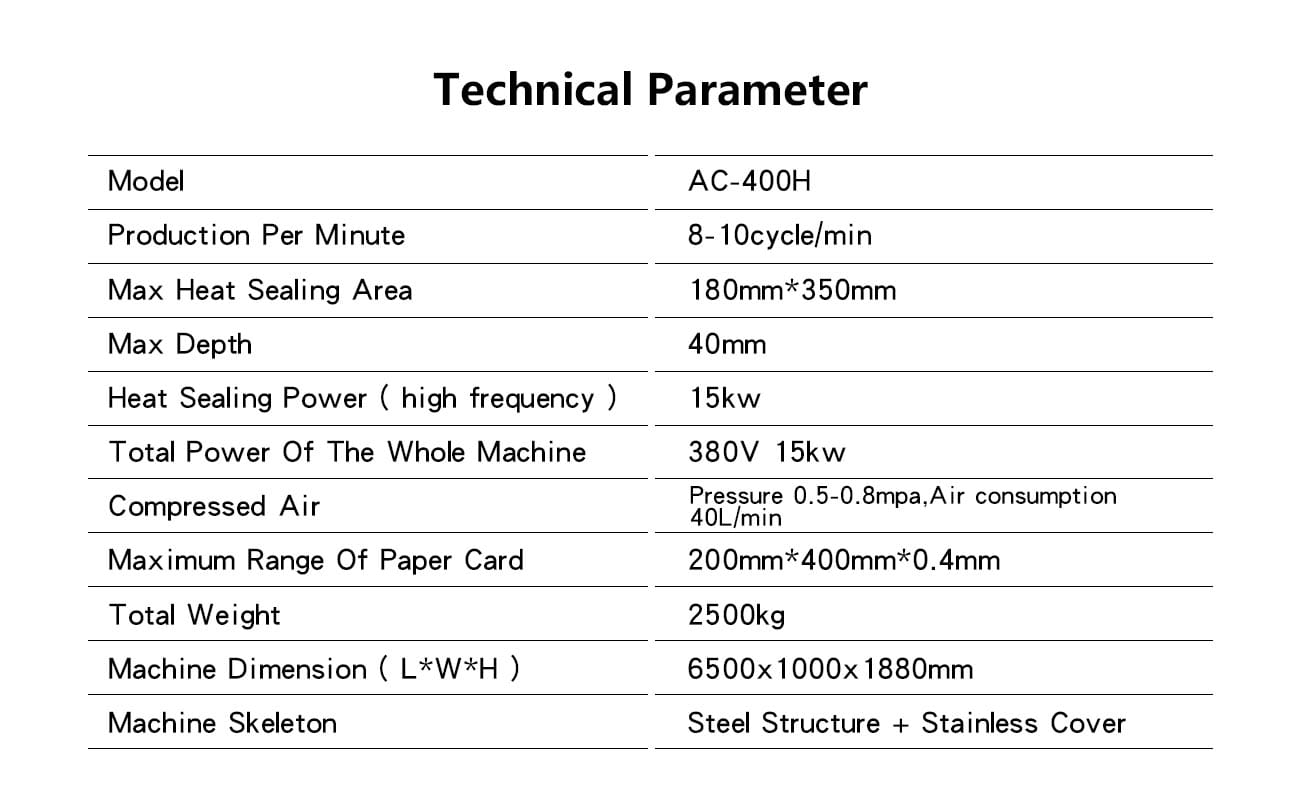

$32,999.00

Technical features:

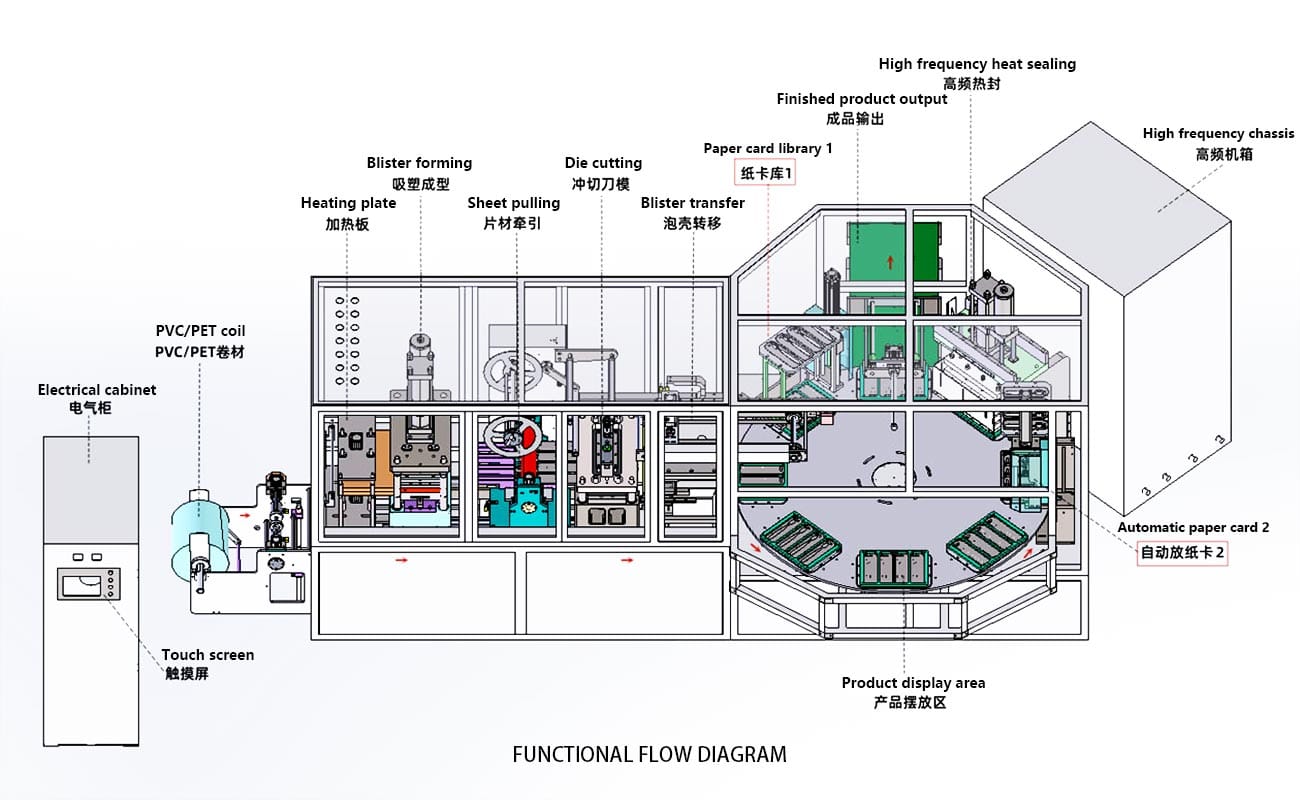

1. The main motor adopts variable frequency speed regulation: the number of punching per unit time is set according to factors such as the length of the formed bubble shell, the feeding speed of the filler, and the heat sealing effect of the hanging card blister.

2. The servo rolling guide mechanism is adopted: the operation is stable, the synchronization is accurate, and the stroke is adjustable.

3. Due to the use of contact plate heating: the power, temperature and time of the heating plate are reduced, and energy is saved. And the stability and reliability of the plastic sheet are enhanced

4. The forming heating plate is automatically opened and closed: the heating plate time can be extended when the machine is turned on, so that the sheet is fully heated, thereby ensuring the reliable forming of the bubble shell and effectively controlling the waste of materials.

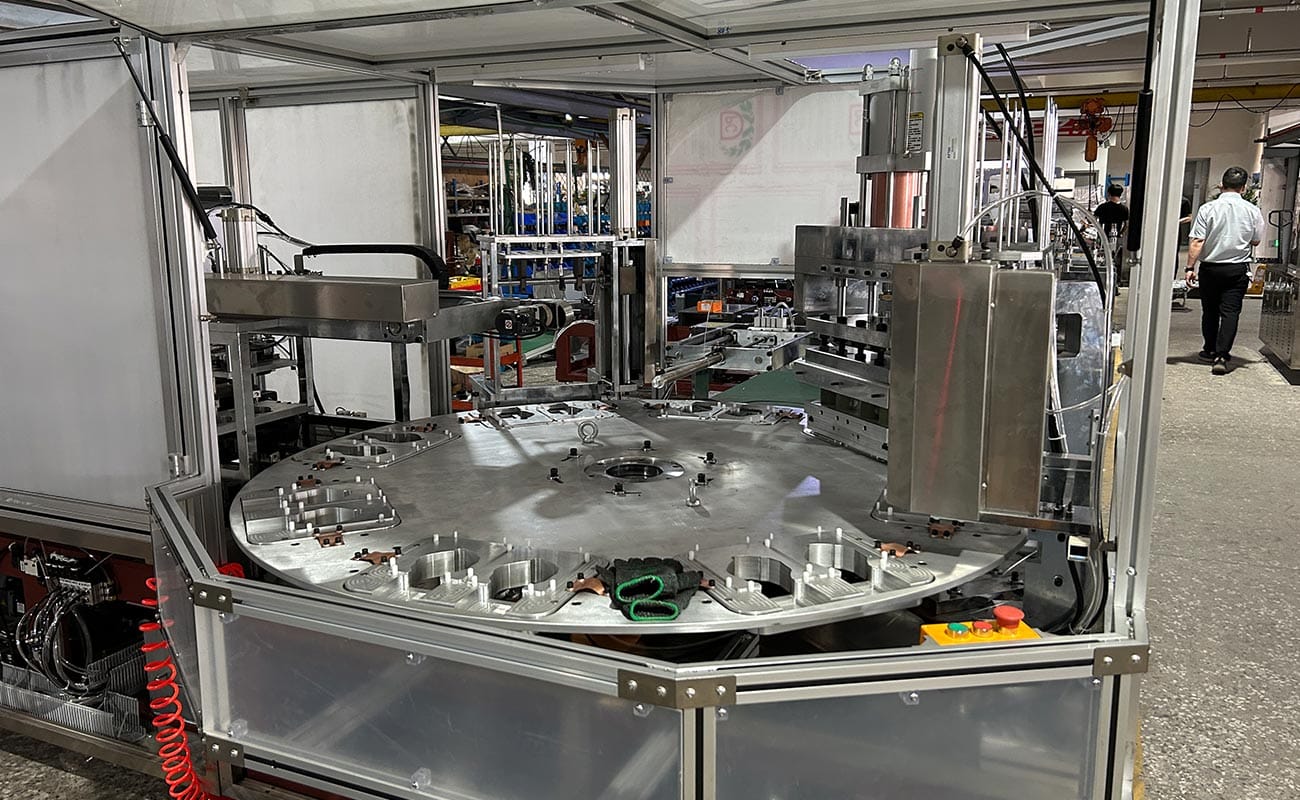

5. Bubble shell heat sealing: disc multi-station, high-frequency heat sealing, double pressure cylinder to achieve rapid heat sealing of the bubble shell and paper card, thereby improving the efficiency of the equipment.

6. The mold is clamped by a pressure plate for easy loading and unloading.

7. The sheet is used up and the sheet is broken. Automatic alarm and shutdown. It is also equipped with an emergency stop safety device to improve the safety of operators during debugging and mold changing.